MAXIMUM ADAPTABILITY

- It can be installed without any physical contact with machines

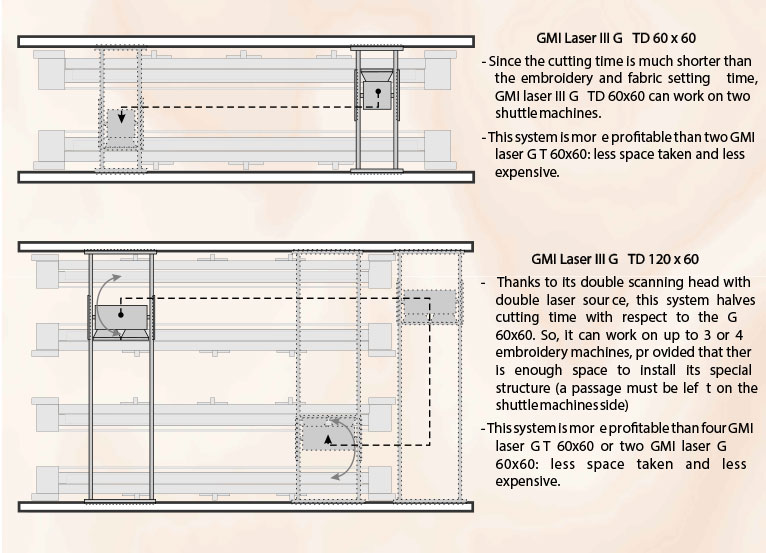

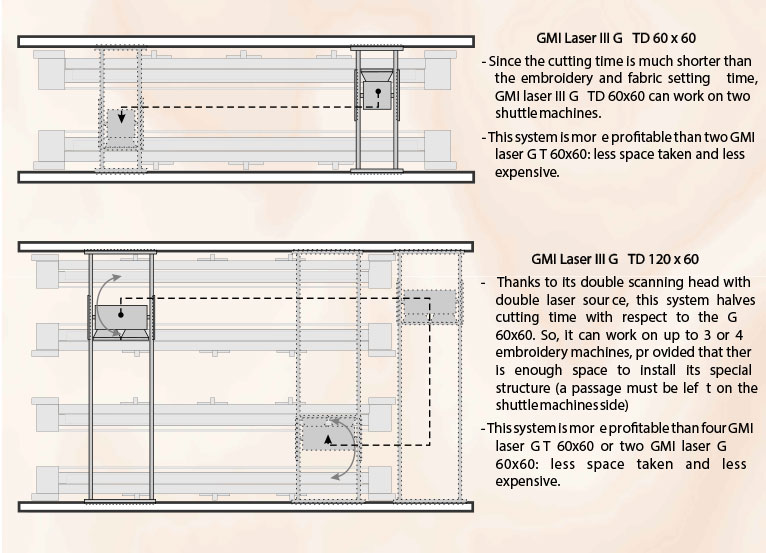

- More than one machine can be served by the same laser

- High precision structure on measure to better manage the space available

POWERFUL AND RELIABLE

- LASER SOURCE: CO sealed, nominal power 100W (GTD 60x60) or 200W (double source 100W - GTD 120x60)

LASER GALVO-HEAD

- The laser beam is directed, at high speed and great precision, by special mirrors driven by electromagnetic motors

BRUSHLESS ENGINES for laser column movements

WATER COOLING SYSTEM

- Temperature variations don't affect the laser output power

- Better control of cutting positions

SAFETY

- Bell protecting from laser beams

- Radar devices for detecting the presence of persons and/or things inside the work area during machine movements

- Different solutions for rear protection according to the type of installation

- Adding cushions with sensors for immediate stop

NEW VERSION:THREE-AXIS (GALVONOMETRIC LASER HEAD)

This new technology allows to get better performances:

LARGE WORKING AREA 600 X 600 mm (GTD 60x60)

or 1200 X 600 mm (GTD 120x60) with go+return cut

- Fewer laser column (X) and embroidery loom (Y) movements: ie. in “all over” designs.

- Fewer junctions

VERY SMALL LASER SPOT

- Higher speed with same laser power source

- Less burning while cutting the same fabric

- Better definition of corners and small details

FOCUSING BY DYNAMIC BEAM EXPANDER

- Higher cut control (you can cut the fabric without boring the underneath fabric)

- More linear cuts

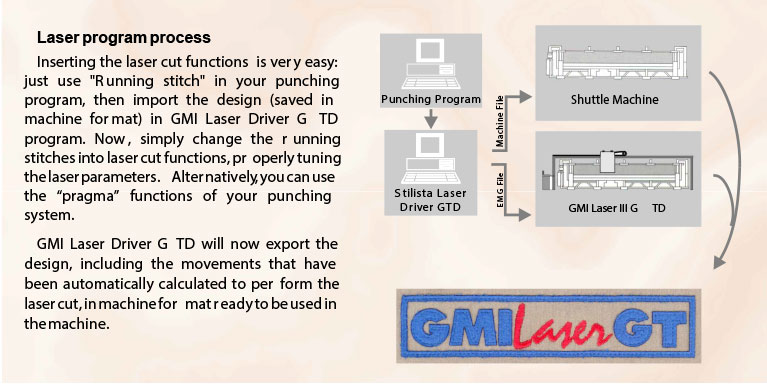

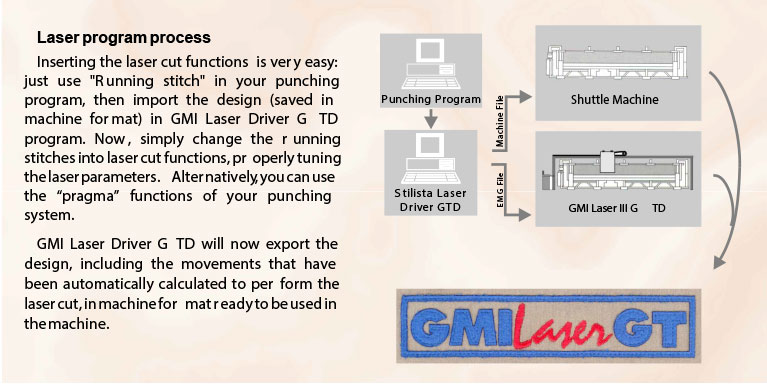

“STILISTA 2000 LASER DRIVER" CONTROL SOFTWARE

- GMI invented the bridge laser cut for embroidery machines and is currently the firm having the greatest number of machines installed in Italy and throughout the world. This solid experience, applied to software development, guarantees the high quality of Stilista 2000 Laser Driver, which is undoubtedly the most exhaustive and easy to use control software.

Option: GMI Roller

- Unroller -Roller to work with piece-goods.

- It must be positioned under the GMI Laser GTD, near the embroidery machine.

- The GMI Laser GTD will automatically shift on the Roller, any time the embroidery machine is stitching. This allows an optimized output and avoids any waste of time of the Laser.

- It engraves and cuts out appliques, while the embroidery machine keeps on working.

- The fabric advance is automatic.